Categories

Hot products

Description of PUF Insulated Panels

PU Sandwich Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core Polyurethane (PU) rigid foam.

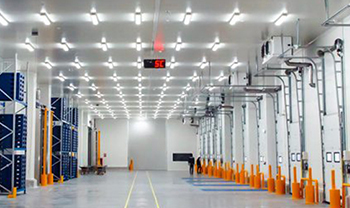

Due to the advantages as heat and sound insulation, high load capacity, light weight (about 10kg/m2), quick movement and easy to install, PU Sandwich Panel are procured with the best prices and used in the buildings whose load-bearing system is of steel and prefabricated concrete, such as industrial buildings, military buildings, social buildings, agricultural buildings, sports facilities, construction sites, silos, hypermarkets, shopping malls, cold storage depots and marketplaces.

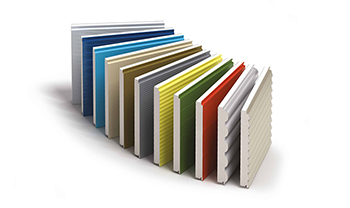

The products to meet the requirements of any kind of architectural project are produced with aluminum or dyed galvanized sheet metals, in requested amounts and dimensions at BRD Sandwich Panel.

.jpg)

Due to the advantages as heat and sound insulation, high load capacity, light weight (about 10kg/m2), quick movement and easy to install, PU Sandwich Panel are procured with the best prices and used in the buildings whose load-bearing system is of steel and prefabricated concrete, such as industrial buildings, military buildings, social buildings, agricultural buildings, sports facilities, construction sites, silos, hypermarkets, shopping malls, cold storage depots and marketplaces.

The products to meet the requirements of any kind of architectural project are produced with aluminum or dyed galvanized sheet metals, in requested amounts and dimensions at BRD Sandwich Panel.

.jpg)

Specifications of PU Sandwich Panel

| PU Sandwich Roof Panel | |

| Structure | three layers: |

| (1)upper layer is steel sheet, | |

| (2)the inner layer is PU sandwich, | |

| (3)the bottom layer is also steel sheet | |

| Steel Thickness | 0.4~0.7mm |

| Panel thickness | 50--200 mm |

| Length | 1-11.8m |

| Effective width | 1000mm |

| Core material | polyurethane foam |

| Density | 40--45(kg/m³) |

| color | Ral Color |

| Parts | Steel line for easy connect one by one Film covering in order to protect the steel of panels |

| Lifetime | 20-35 years |

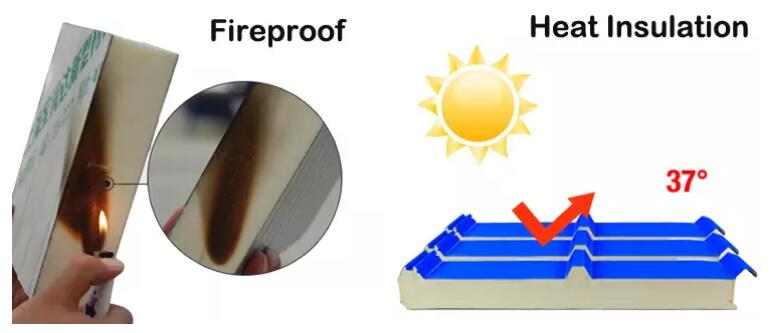

| Character | Light in weight, heat insulation, fireproof and waterproof,environmental |

| Usage | the large size factory buildings,storages, exhibition halls, gymnasiums ,etc |

| Packing | Packed by shipping Container or according to your demands |

Features of Sandwich PUF Panel

- Major savings in energy cost

- Light weight and easy installation

- High standard of thermal insulation

- Can be produced rapidly and on demand in the required quantity and length

- Can be easily transported to wherever they are needed

- Lower cost solution compared to traditional building materials

- Saves construction and maintenance cost

- Provides durability and long life

Advantage

-

Strong bearing capacityCreated exclusively 4 wave roof panel in China for the first time, more powerful for snow load.

Strong bearing capacityCreated exclusively 4 wave roof panel in China for the first time, more powerful for snow load. -

Beautiful waterproofExclusively adopt the 3 wave roof, embedded installation, dark nail waterproof technology, easy installation, guarantee 100% hold water.

Beautiful waterproofExclusively adopt the 3 wave roof, embedded installation, dark nail waterproof technology, easy installation, guarantee 100% hold water. -

Super flame retardationThe coefficient of thermal conductivity is 0.023w/(m•k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits.

Super flame retardationThe coefficient of thermal conductivity is 0.023w/(m•k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits. -

Easy and quick installationCompared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.

Easy and quick installationCompared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.

.jpg)

.jpg)

.jpg)