Categories

Hot products

Description

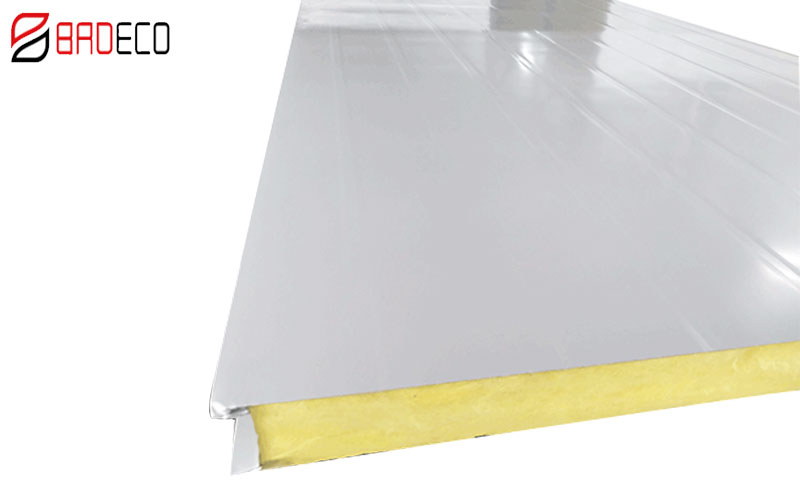

Glass wool sandwich panel uses vertical-hair shaped glass wool as inner side, colored steel sheets as outer side, after formed outer side, after formed by automatically machine, then adhered with super glue.

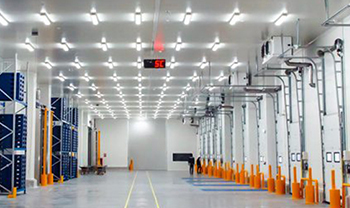

It is good in fireproofing because colored steel sheet and rock wool doesn’t flame.It is widely used in the steel structure factory building, activities room, roof, wall, air clean room ceiling and partition.

It is good in fireproofing because colored steel sheet and rock wool doesn’t flame.It is widely used in the steel structure factory building, activities room, roof, wall, air clean room ceiling and partition.

Specifications

| Panel characteristics | Panel thickness [mm] | |||||||

| 50 | 75 | 100 | 150 | 200 | ||||

| Functions |

|

|||||||

| Standard Facings |

|

|||||||

| Steel thickness [mm] | 0.4, 0.5, 0.6, 0.7, 0.8 | |||||||

| Rock wool core material | density 100 / 120 kg/m³ | |||||||

| Panel areal weight [kg/m²] | 15.50 | 18.50 | 22.5 | 30.00 | 36.50 | |||

| Thermal conductivity λD[W/mK] | 0.043 | |||||||

| Thermal transmittance U-value [W/m²K] |

0,63 | 0,48 | 0,39 | 0,27 | 0,20 | |||

| Acoustic insulation [dB] | 27 | |||||||

| Length [mm] | As customized | |||||||

| Effective width [mm] | 1000mm(option 950,1150) | |||||||

| Reaction to fire | - | A2-s1, d0 and NRO | ||||||

| Fire resistance | - | EI 90 / E 120 | E 120 / EW 60 | |||||

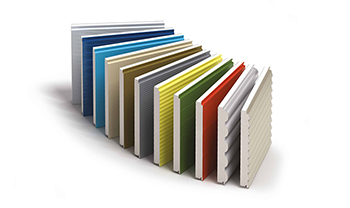

Various Color Choice

Advantage

-

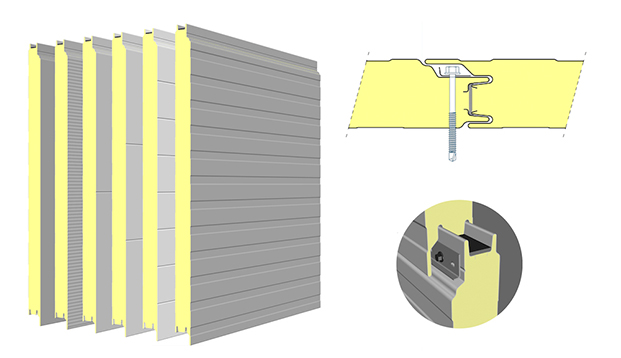

INSTALLATIONEasy and quick to install

INSTALLATIONEasy and quick to install -

EconomicsSignificant savings in site installation costs,energy saving thermal insulation

EconomicsSignificant savings in site installation costs,energy saving thermal insulation -

BeautifulPanel comes in a range of aesthetically pleasuring colors

BeautifulPanel comes in a range of aesthetically pleasuring colors -

FireproofGood reactions to fire properties

FireproofGood reactions to fire properties -

DurableLong lasting, stood the test of time in the extremes of harsh climate

DurableLong lasting, stood the test of time in the extremes of harsh climate

Sandwich Panel Assembly

1, First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

2, Before the installation of wall panel, it should check whether the verticality and levelness of metope purlin installation requirements, wall frame column vertical degree meets the requirement.

3, Before installation polyurethane wall panel, it should first mounting plate bottom water retaining plate and the bottom of the window to block water board, water retaining plate and wall frame beam connection with self tapping screw fixation.

4, Polyurethane wall panel links with ground.

Lateral links: fixed polyurethane sandwich panel with the ground at the other end of the round hole with steel frame fixed, connection between the two plate mouth involution, if occurrence crack of the connectors available heat preservation to fill.

Vertical links: the gap between plates, using the dedicated button concave groove in the fixed wall panel.

2, Before the installation of wall panel, it should check whether the verticality and levelness of metope purlin installation requirements, wall frame column vertical degree meets the requirement.

3, Before installation polyurethane wall panel, it should first mounting plate bottom water retaining plate and the bottom of the window to block water board, water retaining plate and wall frame beam connection with self tapping screw fixation.

4, Polyurethane wall panel links with ground.

Lateral links: fixed polyurethane sandwich panel with the ground at the other end of the round hole with steel frame fixed, connection between the two plate mouth involution, if occurrence crack of the connectors available heat preservation to fill.

Vertical links: the gap between plates, using the dedicated button concave groove in the fixed wall panel.

.jpg)

.jpg)

.jpg)