Categories

Hot products

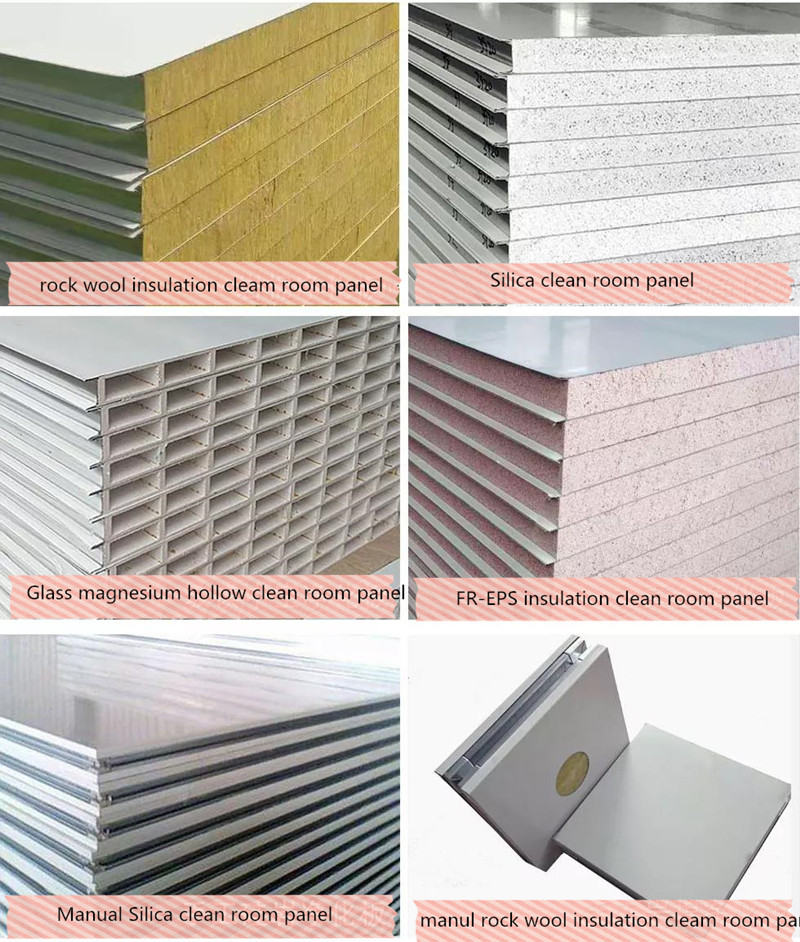

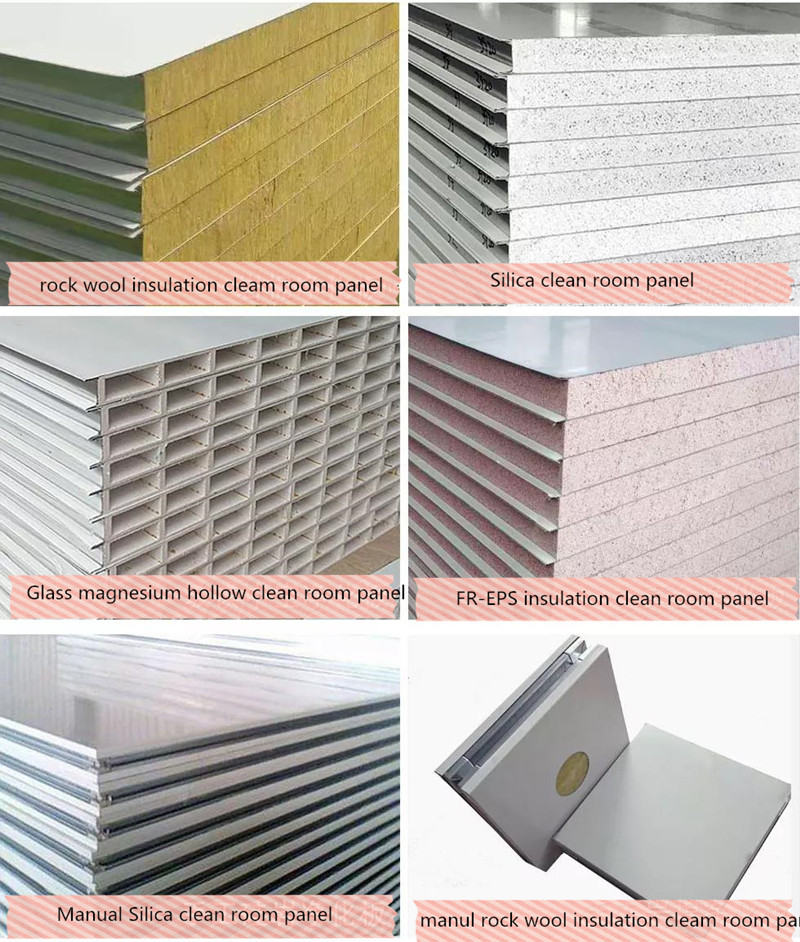

Description of Clean Room Panel

Clean Room Panel, also known Purification board is a composite board made of color-coated board, stainless steel and other materials as a surface material. Because of its unique dustproof, antistatic, antibacterial and other effects, it is widely used in electronics, pharmaceuticals, food, biology, aerospace Aerospace, precision instrument manufacturing and scientific research, etc. have strict requirements on the indoor environment in the field of purification engineering.

Specifications of Clean Room Panels suppliers

| No. | Item | Specification |

| 1 | Surface | PCGI/PPGI/Stainless steel |

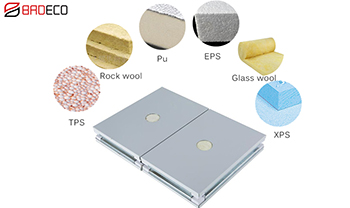

| 2 | Core Material | Polyurethane,rock wool ,eps,glass wool,XPS,TPS |

| 3 | Width | 980/1180mm |

| 4 | Length | Customized |

| 5 | Thickness of steel | 0.25-0.8mm |

| 6 | Thickness of core material | 50-200mm |

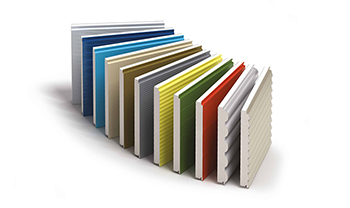

| 7 | Color | White, blue, red or customized |

| 8 | Advantage | Insulation, fireproof, high strength |

| 9 | Application | Indoor wall panels for purification of medicine, electronics, biological research, food, beverages, etc. |

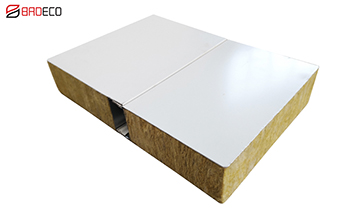

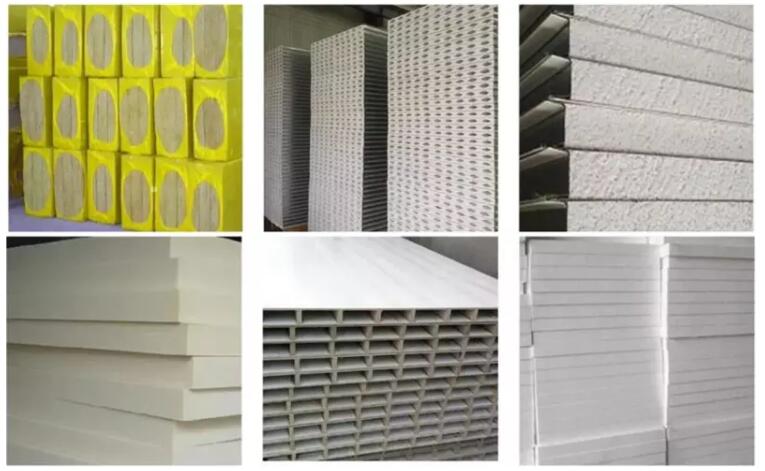

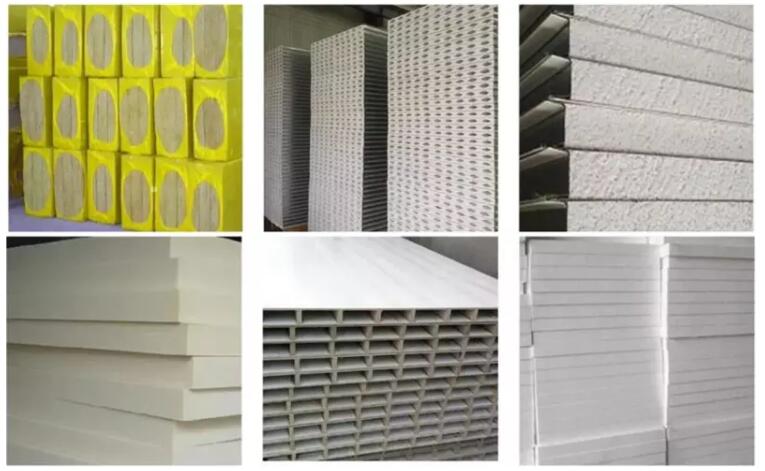

The Clean room panel structure

The Clean composite board is also called clean (room) sandwich panel use rock wool, glass wool, Paper honeycomb, ceramic aluminum plate, glass magnesium plate Paper honeycomb as insulation core material, use Color steel plate, galvanized plate, aluminum zinc plate, stainless steel, printed steel plate, aluminum foil, PVC, plywood as panel sheet.

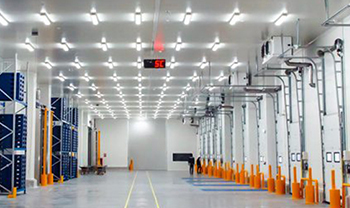

Purification/Clean workshop

What is the most important role of the purification workshop?

The most important role of the purification workshop is to control the cleanliness, temperature and humidity of the atmosphere contacted by the products, so that the products can be produced and manufactured in an excellent environmental space, which we call the purification workshop.

Dust free workshop

Clean workshop is also called clean workshop, clean room and clean room.

Clean room, also known as clean room or clean room. It is the basis of pollution control. Without clean room, it is impossible to produce pollution sensitive parts in batch. In fed-std-2, a clean room is defined as a room with air filtration, distribution, optimization, construction materials and devices, in which specific regular operating procedures are used to control the concentration of airborne particles, so as to achieve the appropriate level of particle cleanliness.

Purification/Clean workshop

What is the most important role of the purification workshop?

The most important role of the purification workshop is to control the cleanliness, temperature and humidity of the atmosphere contacted by the products, so that the products can be produced and manufactured in an excellent environmental space, which we call the purification workshop.

Dust free workshop

Clean workshop is also called clean workshop, clean room and clean room.

Clean room, also known as clean room or clean room. It is the basis of pollution control. Without clean room, it is impossible to produce pollution sensitive parts in batch. In fed-std-2, a clean room is defined as a room with air filtration, distribution, optimization, construction materials and devices, in which specific regular operating procedures are used to control the concentration of airborne particles, so as to achieve the appropriate level of particle cleanliness.

Application

1. The clean board is used for the internal partition walls and suspended ceiling of the building, and also for the wall of the mobile container house;

2. The clean board has good self-supporting performance;

3. The clean board has good air tightness;

4. The clean board has good thermal insulation and anti-cold bridge functions;

5. The surface layer of thecleanplate can be color-coated steel plate, aluminum-zinc plated steel plate and stainless steel;

2. The clean board has good self-supporting performance;

3. The clean board has good air tightness;

4. The clean board has good thermal insulation and anti-cold bridge functions;

5. The surface layer of thecleanplate can be color-coated steel plate, aluminum-zinc plated steel plate and stainless steel;

.jpg)

.jpg)

.jpg)

.jpg)